Printing through electro-photographic imaging or LED arrays.

Relies on photoconductive materials that conduct electricity when exposed to light.

Most laser printers are monochrome only.

These printers use a LOT of electricity.

Laser printers that print color can produce spot colors which are vibrant and high quality.

Color laser printers use CMYK as 4 separate toner cartridges

Relies on photoconductive materials that conduct electricity when exposed to light.

Most laser printers are monochrome only.

These printers use a LOT of electricity.

Laser printers that print color can produce spot colors which are vibrant and high quality.

Color laser printers use CMYK as 4 separate toner cartridges

Process

Processing

- PC creates Raster images

- PC uses printer’s Raster Image Processor driver to turn raster image into a series of commands to the laser.

- Images are sent to the printer spooler, which handles print jobs

- Printer spooler sends print job to printer

- Commands are stored in RAM

- Insufficient memory results in Memory Overflow errors.

- You can reduce image resolution or color depth to reduce filesize

- You can disable Resolution Enhancement Technology

- Images that are too complex will result in complexity errors

- Insufficient memory results in Memory Overflow errors.

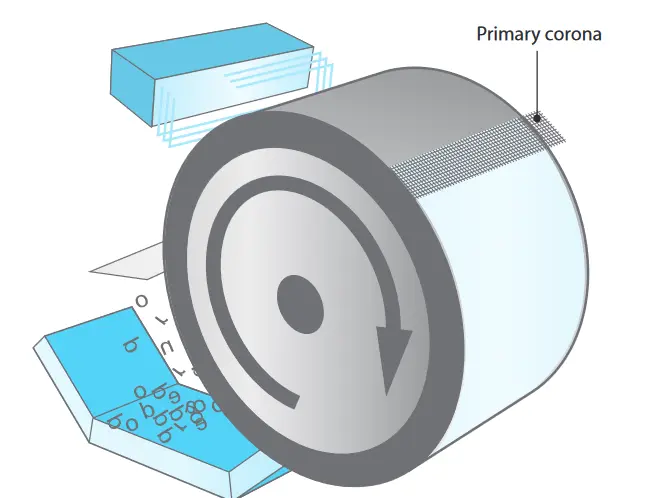

Charging

Primary Corona Wire applies a uniform 600V - 1000V negative charge to entire surface of Drum

Exposing

Laser used to create a remove negative charge on the drum correlating the places where image dots would be

Developing

Particles with less negative charge (those hit by the laser) will attract toner particles, thereby creating a developed image.

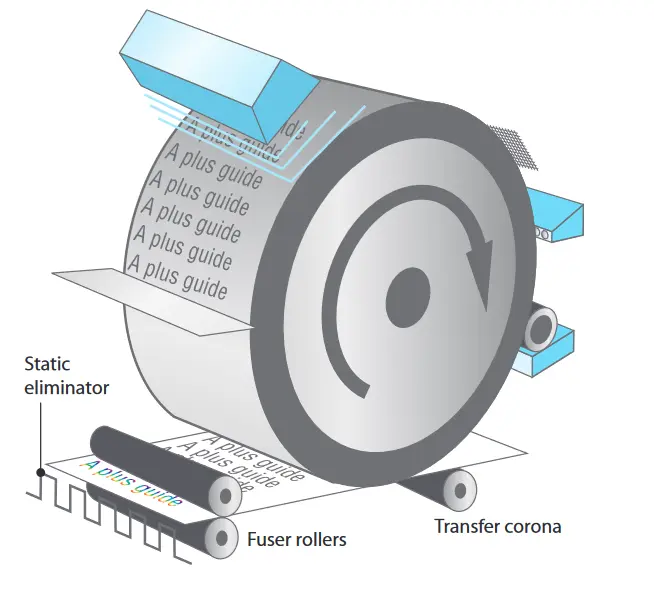

Transferring

Transfer Corona Wire gives the paper a positive charge, allowing the toner to transfer onto the paper.

Fusing

- Pressure roller applies pressure onto the paper

- Heating roller melts toner onto paper, thereby permanently affixing it

- Static discharge eliminator removes paper’s positive charge

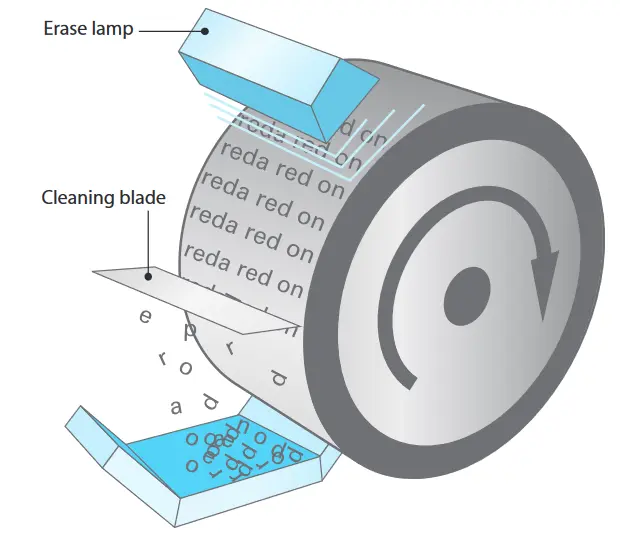

Cleaning

Drum Cleaning

Remove all residual toner by using a rubber cleaning blade along the surface of the drum.

Allow the toner to fall into the cleaning mechanism where it may be reused

Erase lamps can automatically clean the drum by using UV lights to remove toner.

Allow the toner to fall into the cleaning mechanism where it may be reused

Erase lamps can automatically clean the drum by using UV lights to remove toner.

Components

Toner

Power bonded with pigment. Black toner is typically carbon + polyester resin

Toner Cartridge

Supplies toner to apply to the page.

Supplies toner to apply to the page.

Imaging Drum

Aluminum cylinder coated with photosensitive compounds.

When light hits these compounds, electrical charge drains to the grounded cylinder, allowing it to apply toner onto the paper.

Aluminum cylinder coated with photosensitive compounds.

When light hits these compounds, electrical charge drains to the grounded cylinder, allowing it to apply toner onto the paper.

Erase Lamp

Applies light to the imaging drum.

Applies light to the imaging drum.

Primary Corona Wire / Primary Charge Roller

Located close to the imaging drum.

Regulates and then passes voltage into the drum.

Ensures the drum can only receive 600-1000 Volts

Located close to the imaging drum.

Regulates and then passes voltage into the drum.

Ensures the drum can only receive 600-1000 Volts

Transfer Corona Wire / Transfer Charge Roller

Transferring image from drum to paper by attracting negatively charged toner particles to the positively charged page.

A static charge eliminator is then used to eliminate charge from the page.

Should be cleaned regularly with denatured alcohol

Transferring image from drum to paper by attracting negatively charged toner particles to the positively charged page.

A static charge eliminator is then used to eliminate charge from the page.

Should be cleaned regularly with denatured alcohol

Laser

Writes onto the paper by sending charge to the imaging drum

Writes onto the paper by sending charge to the imaging drum

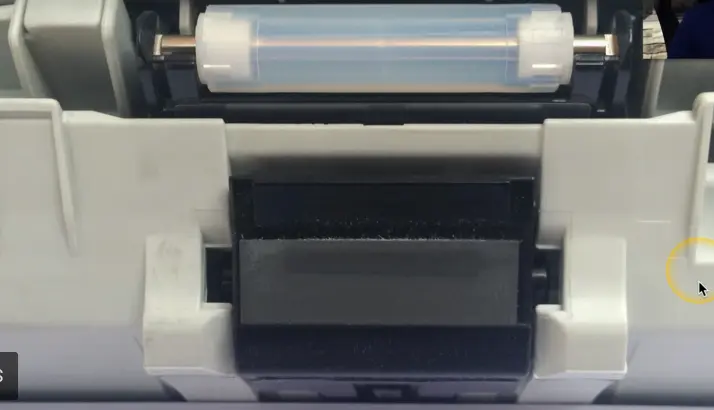

Fuser Assembly

A pressure roller and heating roller are used to melt toner on the page so it can be fused permanently.

The heating roller uses Teflon to avoid toner sticking to it.

A pressure roller and heating roller are used to melt toner on the page so it can be fused permanently.

The heating roller uses Teflon to avoid toner sticking to it.

Transfer Belt and Roller

Used to pick up papers from the pickup roller

Used to pick up papers from the pickup roller

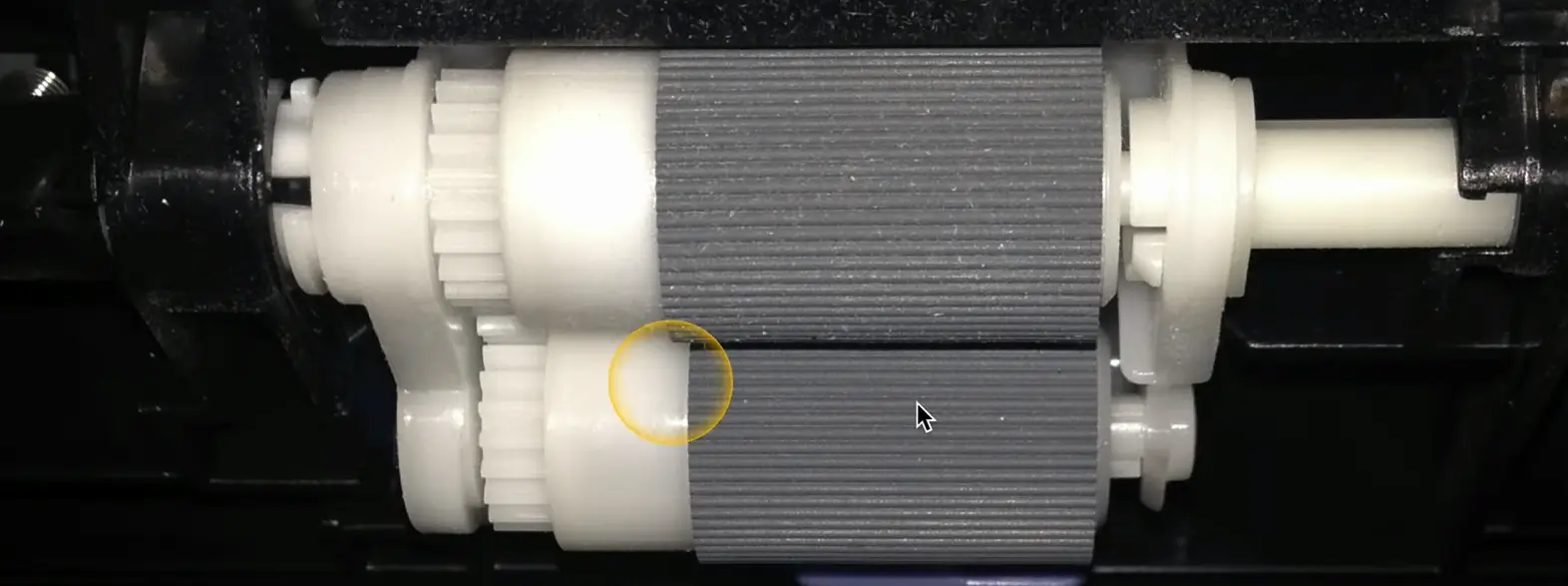

Pickup Roller

Used to grab 1 single page from paper storage or can be fed a paper directly.

Only 1 pages should be in the pickup roller at a time.

Should be cleaned often and replaced if the rollers become smooth

Used to grab 1 single page from paper storage or can be fed a paper directly.

Only 1 pages should be in the pickup roller at a time.

Should be cleaned often and replaced if the rollers become smooth

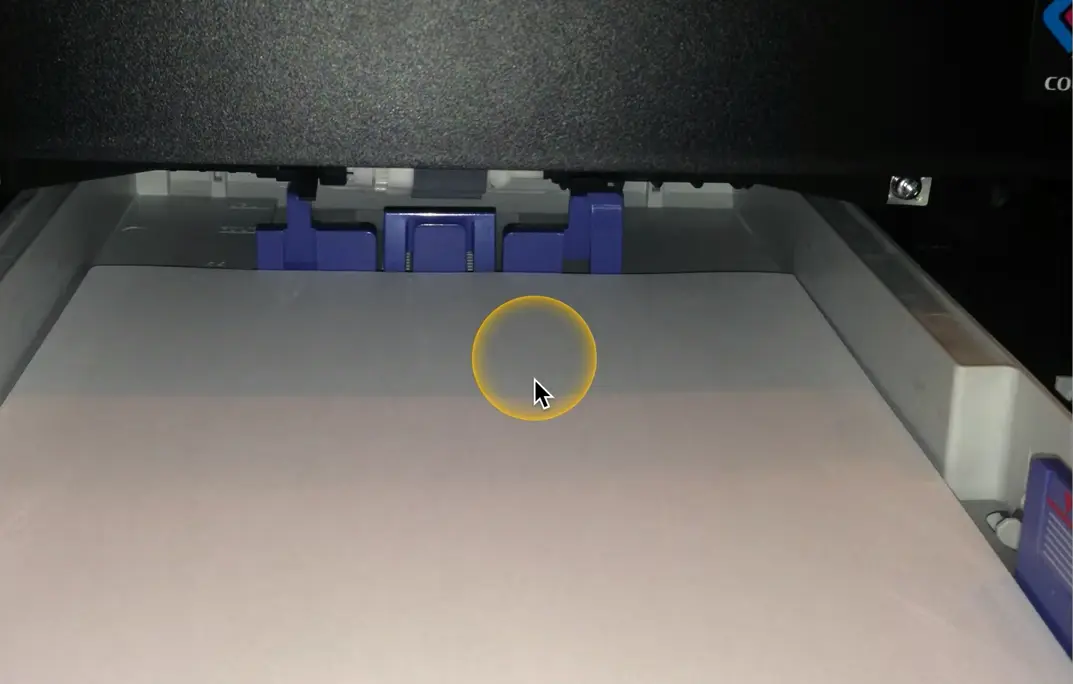

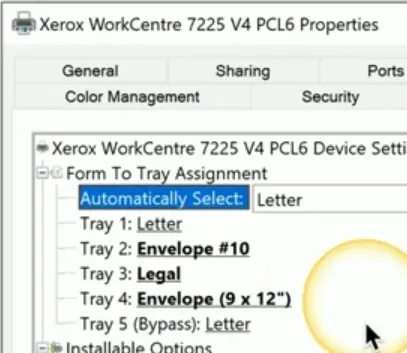

Paper Storage

The trays for blank papers.

The trays for blank papers.

You can have multiple trays made for multiple paper types

You can have multiple trays made for multiple paper types

Separation Pad

Small piece of rubber used to pick 1 page from the paper storage to feed into the pickup roller.

Very common to replace

Small piece of rubber used to pick 1 page from the paper storage to feed into the pickup roller.

Very common to replace

Gearbox

Used to provide the mechanical movements of the:

- Pickup roller

- Separation pad

- Fuser assembly

- Transfer roller

- Duplex system

System Board

Electronic PCB containing:

- ROM for firmware

- RAM to store image before its printed

- CPU

- Optional second ROM for new printer functionality in PostScript You can add SIMM or DIMM RAM for more image storage.

Ozone Filter

The corona creates ozone which is harmful for printer components. The ozone filter should be vacuumed regularly.

Sensors and Switches

Sensors and switches are place throughout the printer to diagnose errors like:

- Paper jam

- Empty paper tray

- Low toner levels

Additional Features

Duplexing

Ability to print on both sides of page without human intervention. Must print one side, turn page over and then print the second side.

Calibration

To fix color issues in the printer and adjust toner usage